Storing Machinery and Equipment in Manufacturing and Engineering Workshops

Neglecting effective storage for engineering workshop equipment can lead to detrimental consequences.

Tools and machinery may become damaged, lost, or stolen due to improper handling and exposure to environmental factors.

Inefficiency arises from wasted time searching for misplaced items, while safety risks increase due to clutter and disorganised workstations.

Ultimately, this can result in decreased productivity, higher operational costs, and potential hazards for employees.

In this guide, we’ll discuss how to store engineering workshop equipment, along with effective storage solutions. This will help you create a well-organised and efficient workspace that maximises productivity and safety.

At Polstore Storage Systems, we’ve helped countless engineers across the UK design and implement workshop spaces that meet their unique needs.

For a comprehensive workshop setup tailored to your specific needs, contact our team today to explore our range of storage solutions and expert design services.

Call us on +44 800 008 6861 or complete our online enquiry form.

The Importance of Efficient Workshop Storage

A cluttered workshop is more than just an eyesore; it’s a productivity killer. Misplaced tools, damaged equipment, and wasted time searching for items can significantly impact your bottom line.

There are many reasons why effective storage is essential in an engineering workshop. Proper storage can maintain equipment lifespan, create efficiency, and improve safety.

Implementing a robust storage system offers numerous benefits:

- Improved efficiency: Quickly locate tools and materials, reducing downtime.

- Enhanced safety: Prevent accidents by storing sharp tools and hazardous materials securely.

- Prolonged tool life: Protect equipment from damage by storing it correctly.

- Better workspace organisation: Create a clean and safe working environment.

Key Storage Principles

To maximise the benefits of workshop storage, consider the following principles:

- Categorisation: Group similar tools and equipment together for easy retrieval.

- Accessibility: Ensure frequently used items are easily accessible.

- Durability: Invest in high-quality storage solutions that can withstand heavy use.

- Flexibility: Choose storage systems that can adapt to changing needs.

- Safety: Prioritise safety by securely storing hazardous materials and sharp tools.

How to Store Engineering Workshop Equipment

Here’s how engineering workshops can optimise their storage solutions to meet the challenges of modern manufacturing.

Organisation and Categorisation

- Group similar tools: Tools should be categorised based on their function or type. For instance, hand tools, power tools, measuring instruments, and cutting tools can be grouped separately.

- Label clearly: Clear labelling of storage containers and shelves helps in quick identification and retrieval.

- Designated areas: Assign specific areas for different types of equipment to maintain order.

Storage Solutions For Your Workshop

A variety of storage solutions are available to suit different workshop layouts and equipment types. Consider these options:

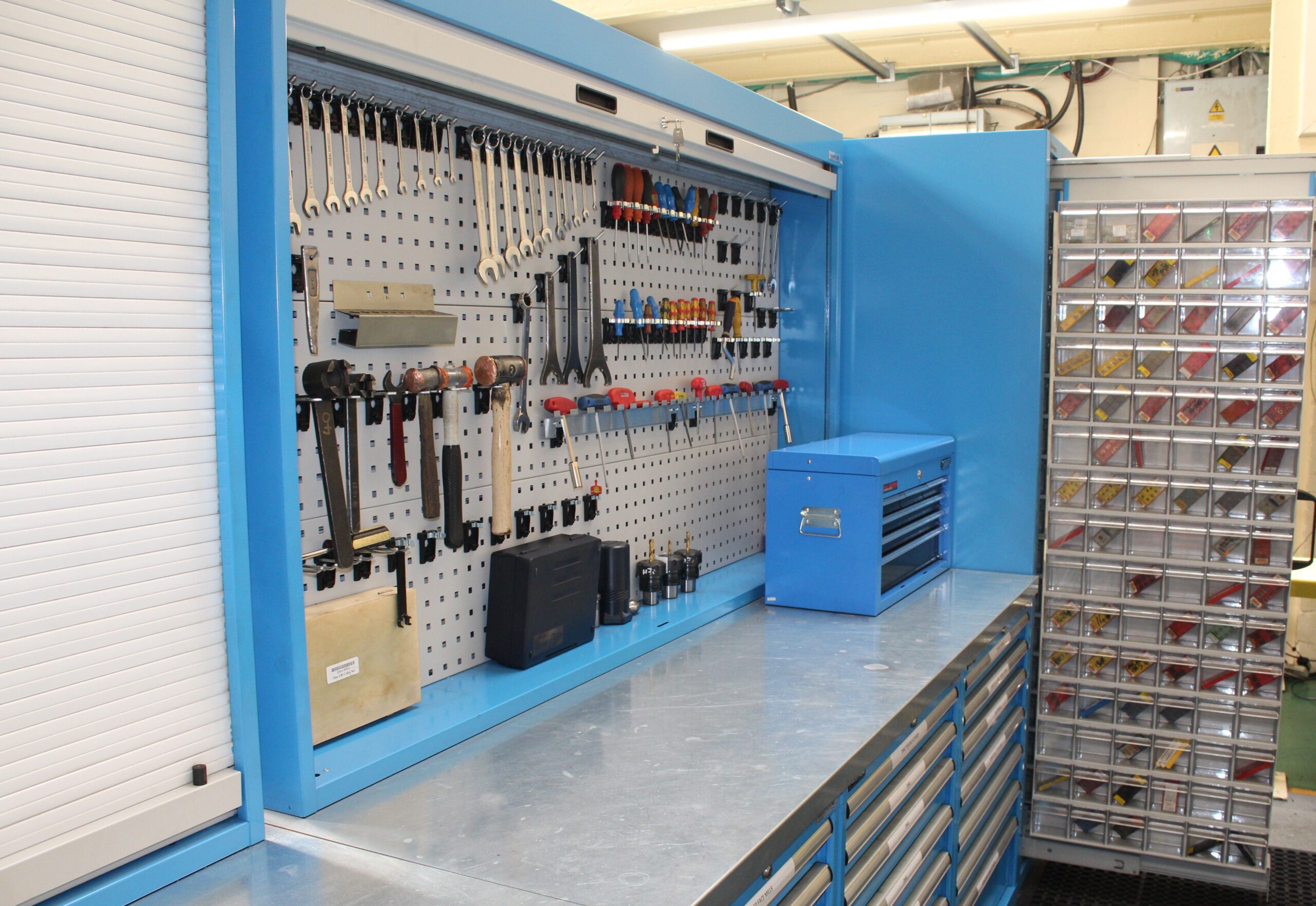

- Tool cabinets and chests: Ideal for storing hand tools, measuring instruments, and small power tools.

- Pegboards: Perfect for hanging frequently used tools, keeping them within easy reach.

- Shelving units: Provide versatile storage for larger equipment, materials, and supplies.

- Modular workbenches: These can be customised to specific needs.

- CNC tool storage racks: Perfect for specialised equipment.

- Toolboxes: Portable options for carrying tools to different work areas.

- Drawer organisers: Ideal for small parts, fasteners, and accessories.

- Wall-mounted storage: Systems to maximise floor space.

At Polstore, we offer a range of durable, purpose-built storage solutions designed for the demands of engineering workshops.

Protection and Maintenance

- Corrosion prevention: Store tools in dry conditions, away from moisture. Consider using anti-corrosion coatings or lubricants.

- Dust and debris: Regularly clean tools and storage areas to prevent buildup.

- Proper handling: Handle tools with care to avoid damage.

- Regular inspection: Check equipment for wear and tear and perform necessary maintenance.

Safety Considerations

- Hazardous materials: Store flammable or hazardous materials in designated, secure areas.

- Heavy equipment: Ensure heavy equipment is stored safely to prevent accidents.

- Ergonomics: Design storage solutions to minimise physical strain during tool retrieval.

Specific Equipment Considerations

- Power tools: Store in a dry place, away from extreme temperatures.

- Measuring instruments: Keep in calibrated cases to protect from damage and ensure accuracy.

- Cutting tools: Store sharp tools securely to prevent accidents.

- Machinery: Cover large machinery when not in use to protect from dust and debris.

Additional Tips

- Optimise space: Utilise vertical space effectively with shelves and hanging storage.

- Regular cleaning: Maintain a clean and organised workshop for safety and efficiency.

- Visual aids: Use visual aids like tool shadows foams to quickly identify missing items.

Engineering Storage Solutions From Polstore

Effective storage of engineering workshop equipment is a critical factor in today’s manufacturing world. By implementing these strategies, engineering firms can create more efficient, safer, and more productive work environments.

This not only contributes to better output and quality control but also helps in attracting and retaining skilled staff – a key concern for many in the industry.

At Polstore, we offer a comprehensive range of storage solutions to transform any space into an efficient workshop. Our product line includes everything from sturdy workbenches and versatile tool cabinets to heavy-duty shelving and specialised racking systems.

Whether you need to store small tools, bulky equipment, or hazardous materials, we have the perfect solution. We also offer custom design and installation services to cater to your unique requirements.

Contact us today to discuss your workshop requirements and let us help you create the perfect workspace.

Call us on +44 800 008 6861 or complete our online enquiry form.

FAQs

Why do you need quality storage for engineering workshop equipment?

Quality storage is vital for engineering workshops as it safeguards equipment, enhances efficiency, ensures safety, improves workspace organisation, facilitates asset management, and often meets regulatory requirements. Proper storage prolongs tool life, prevents accidents, and streamlines operations.

How do you maintain and store workshop tools and equipment?

Maintaining and storing workshop tools and equipment involves a combination of care and organisation. Tools should be cleaned thoroughly after use to remove debris and prevent corrosion. Regular inspection for wear and damage is essential. For storage, a clean, dry environment is crucial. Utilise toolboxes, cabinets, or pegboards for organisation and protection. Proper storage prevents damage, and loss, and ensures tools are readily available when needed.

Related Guides:

- 13 Benefits of a Shipping Container Workshop Conversion

- 10 Must-Have Storage Solutions For Your Workshop

- How to Choose the Best Engineering Workshop Furniture

- 5 Things Your Engineering Workshop Must Have

- What is Shadow Board Foam?

- How to Set Up a Workshop

- Warehouse and Industrial Fit Out Solutions

- 5 Workshop Storage Ideas to Organise Your Space

- 4 Reasons Why You Should Invest in Tool Control

- How to Design the Perfect Machine Shop Fitout

- What is a Mezzanine Floor?

- 15 Garage Storage Solutions for Workshop Organisation