Engineering Workshop CNC Tool Storage Fit Outs

Looking to design the machine shop fit out?

Designing the perfect workshop is essential for optimising productivity, efficiency, and safety in any engineering environment.

A well-thought-out machine shop layout not only enhances workflow but also improves accessibility and ensures a smooth operation.

Whether you are setting up a new shop, reorganising your engineering workshop or looking for storage solutions to store new CNC tooling machines, careful planning is crucial.

In this article, we will guide you through designing the perfect machine shop fit out.

At Polstore Storage Systems, we offer workplace fit-out solutions for various industries, from engineering facilities to automotive and military workplaces.

Our services cover the entire fit out process, from initial design concepts to final installation, ensuring a seamless transition to a fully optimised and functional workspace.

If you’d like us to provide a quote for your workspace, get in touch with our team.

Why Does CNC Tool Storage Matter?

CNC machines are the backbone of modern manufacturing processes, and efficient tool storage is paramount for smooth and organised operations.

Proper tool storage ensures easy access to the required tools, minimises downtime and enhances productivity. It also protects expensive and delicate tools from damage, reducing the need for frequent replacements.

Evaluating The Workspace Layout And Machine Placement

Evaluating the available space and determining the optimal machine placement is a critical step in designing the perfect machine shop fit out.

Efficient use of space and strategic machine placement can significantly impact workflow and productivity.

Consider these factors:

- Assess the available floor space and ceiling height to determine the layout possibilities.

- Consider the workflow and arrange the machines in a logical sequence to minimise material handling.

- Place machines with high tool change frequency closer to the tool storage area for easy access.

- Ensure sufficient space between machines for operator safety and ease of maintenance.

The Importance of Accessible Design

Accessible design is an essential aspect of designing the perfect machine shop fit out.

An accessible design not only improves the efficiency of operations but also ensures the safety and well-being of the machine shop personnel.

Here’s why accessible design is crucial:

- Ergonomics: Designing workstations and equipment to suit the ergonomic needs of the operators reduces the risk of musculoskeletal disorders and enhances their comfort and productivity.

- Safety: Ensuring clear and unobstructed pathways, proper lighting, and easy access to emergency exits and safety equipment prevents accidents and promotes a safe working environment.

- Efficiency: An accessible design eliminates unnecessary movements, reduces fatigue, and streamlines the workflow, leading to improved productivity and reduced downtime.

Essential Components of a Machine Shop Fit Out

When designing the perfect machine shop fit out, it is essential to consider the various components that make up a well-functioning workspace.

Key components to include in your engineering workshop:

- Workbenches and workstations: Provide sturdy and spacious workbenches for operators to carry out their tasks comfortably.

- Tool storage solutions: Invest in appropriate tool storage systems that ensure easy access, organisation, and protection of valuable tools.

- Material handling equipment: Incorporate equipment like forklifts, pallet jacks, and conveyors to facilitate the movement of materials and finished products.

- Safety equipment: Install safety measures such as fire extinguishers, safety barriers, and personal protective equipment to ensure a safe working environment.

- Lighting and ventilation: Proper lighting and ventilation systems improve visibility, reduce eye strain, and maintain air quality in the machine shop.

Types of CNC Tool Storage Solutions

Choosing the right tool storage solution can significantly impact the organisation, accessibility, and efficiency of your CNC tools.

Here are some popular types of CNC tool storage solutions:

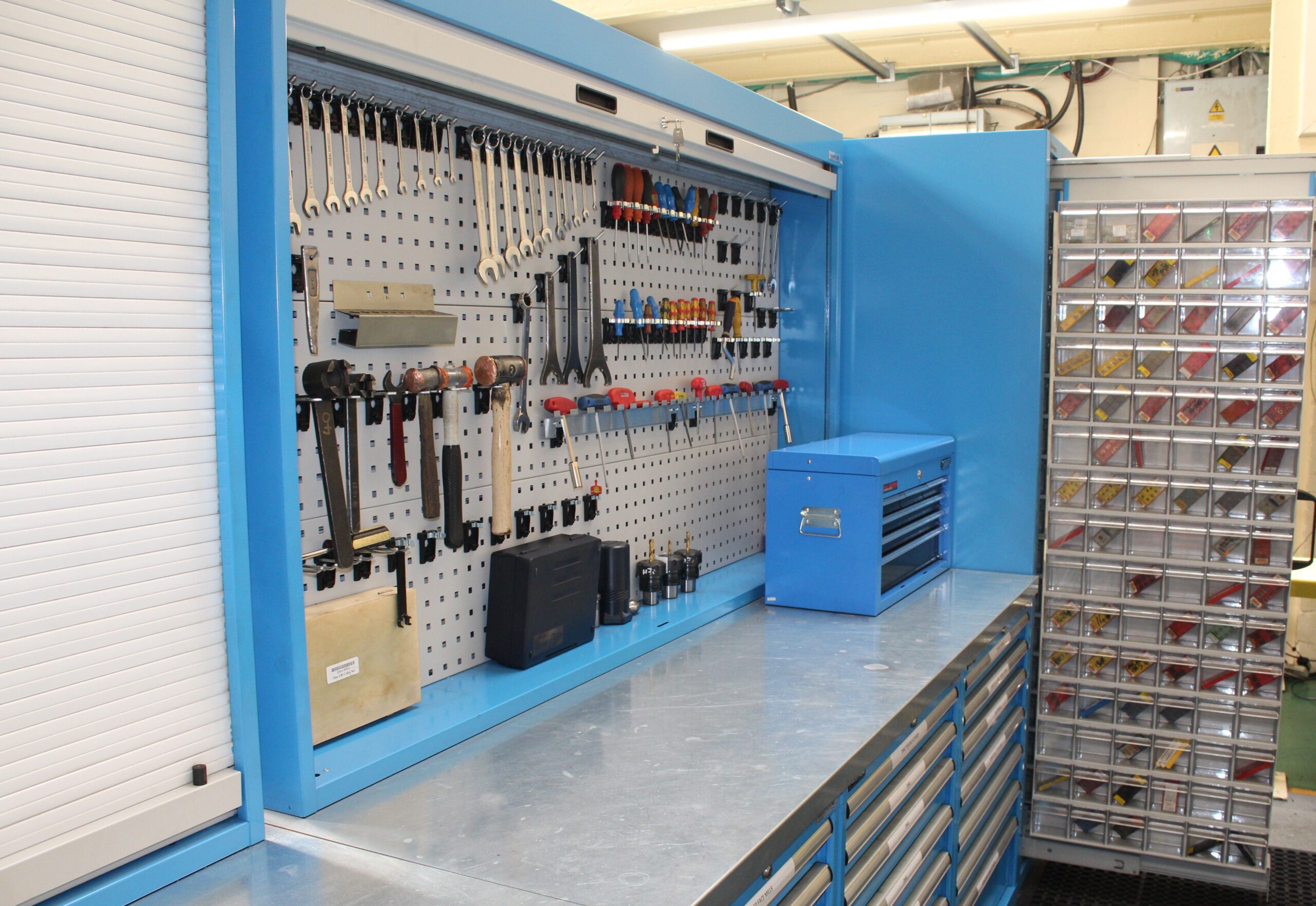

- Tool cabinets and drawers: These provide secure storage for smaller tools and accessories, ensuring easy access and organisation.

- Tool carts or mobile storage units: These portable storage units allow for easy transport of tools and can be moved around the machine shop as needed.

- CNC tool racks and shelves: These provide vertical storage for larger tools and materials, optimising space and accessibility.

Whether you’re looking for one-off storage items, or renovating an entire workshop, we can assist in bringing safe, affordable and practical storage solutions.

Take a look at our range of storage products, or contact our sales team.

Maximising Efficiency with Ergonomic Design

An ergonomic design focuses on creating workspaces and equipment that optimise the comfort, safety, and productivity of the workers.

These are some reasons why ergonomic design can maximise efficiency:

- Reduced fatigue and improved comfort: Ergonomic workstations and equipment reduce operator fatigue, leading to increased productivity and fewer errors.

- Streamlined workflow: Ergonomic design ensures that tools, materials, and controls are within easy reach, minimising unnecessary movements and improving workflow.

- Enhanced safety: Ergonomically designed equipment reduces the risk of injuries and accidents, creating a safer working environment.

Machine Shop Fit Outs From Polstore

Designing the perfect engineering workshop requires a lot of work to meet your CNC tool storage needs efficiently. If you need help with the design, supply and installation of storage solutions for your engineering workshop, we can help.

At Polstore, we specialise in custom workshop fit-outs, and tailoring storage solutions to optimise your workspace. Our expert team assesses your needs and designs efficient layouts with workbenches, tool cabinets, and shelving systems.

From initial planning to final installation, we deliver functional, durable, and organised workshop environments tailored to your specific requirements. Get in touch with us today.