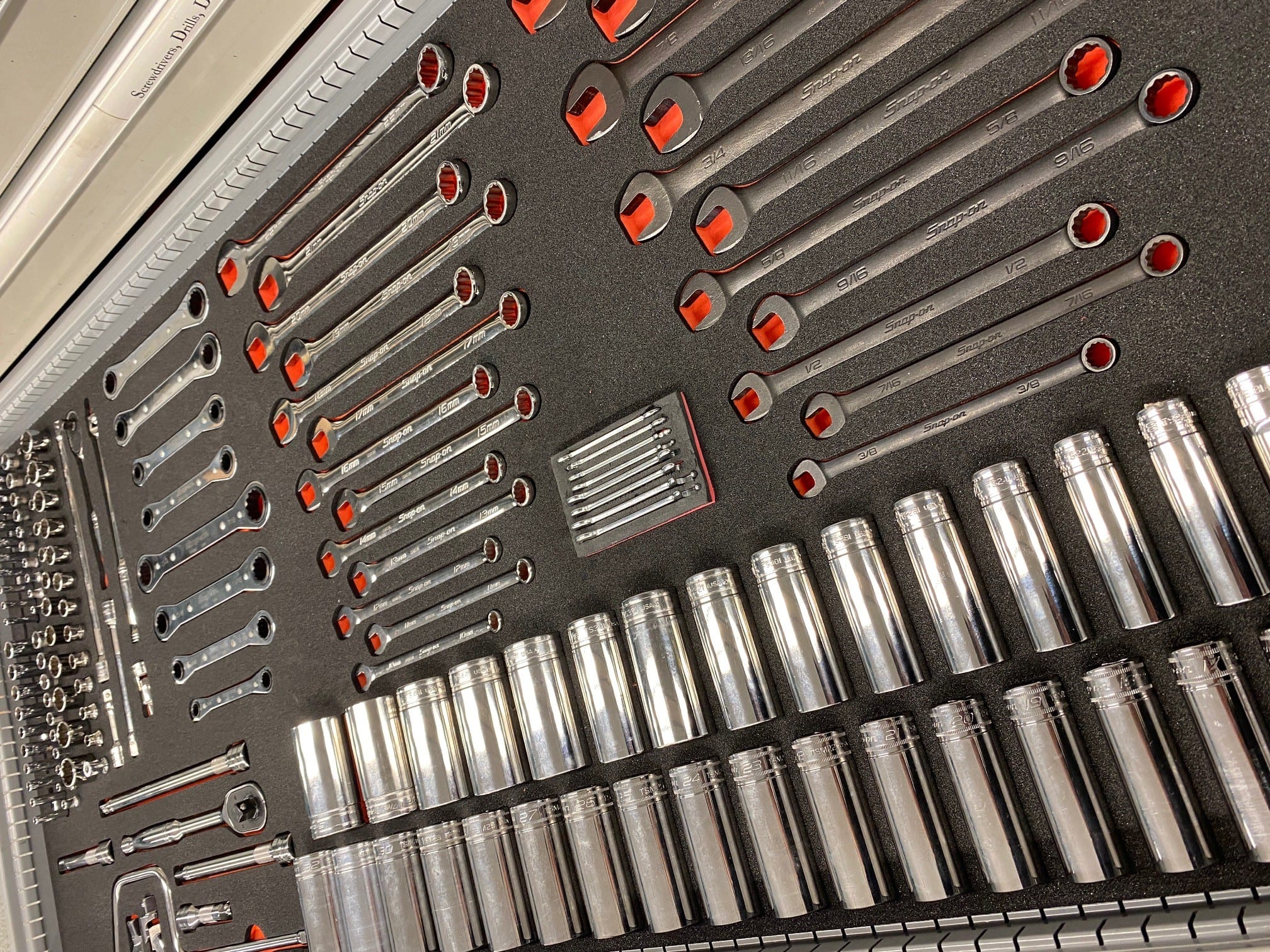

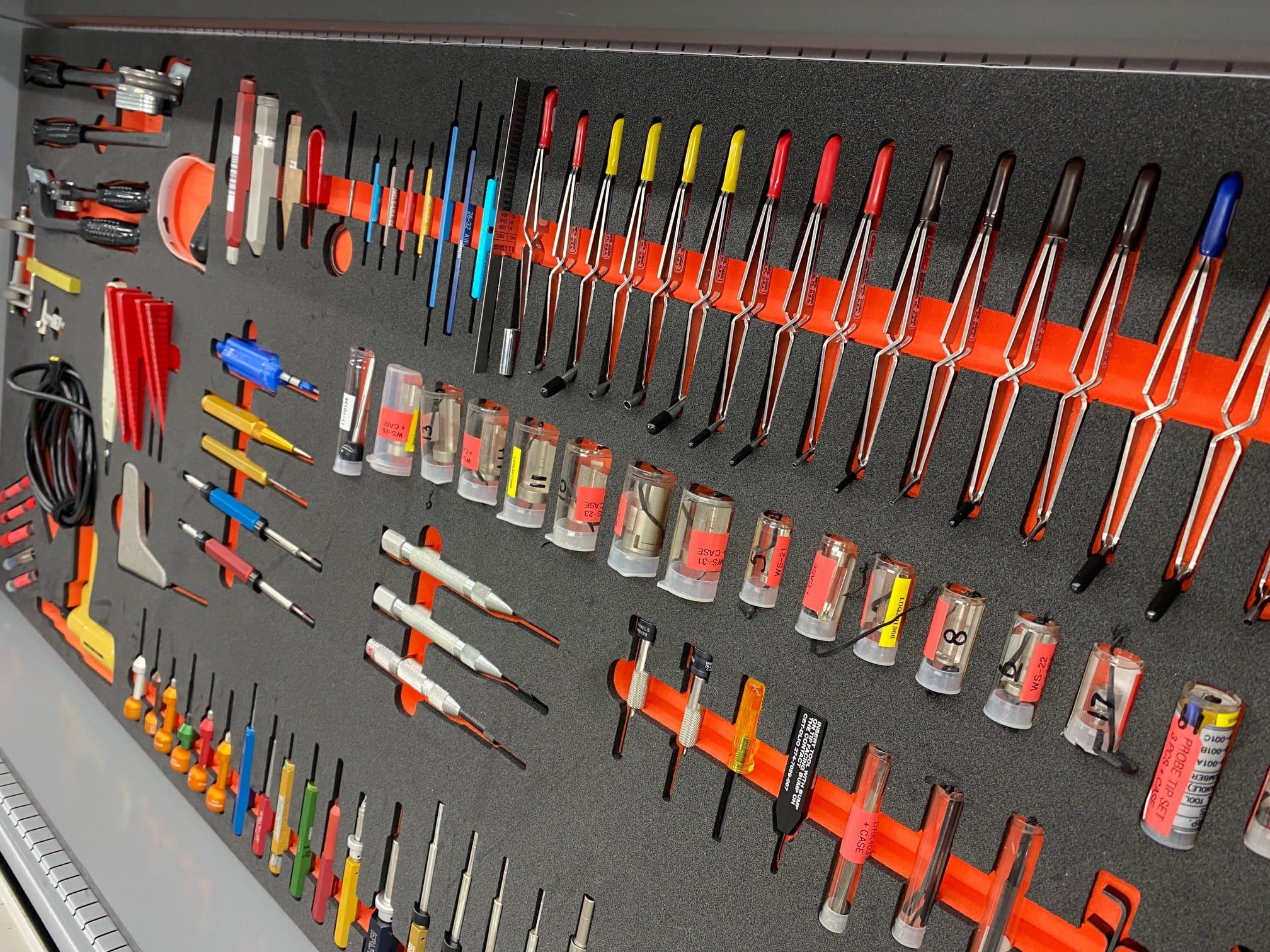

A Work of Art

Tool & Asset Control Foams

Polstore made a bold move and invested in a CNC router machine and design software at the beginning of 2020 to design and manufacture tool and asset control foams; to complement their storage solution offering. After 10 months the result has not only been rewarding but also the learning curve surprising delivering exceptional results.

‘We love it’ says MD Adam Lucas ‘as when you open that draw and see the reaction on the client’s face – it’s the ‘WOW’ factor for sure!’

However, getting to this stage has been a stressful undertaking and some serious training and internal workshops have been required. The amount of detail required to finalise a foam layout can be complex.

The benefit for the client is that Polstore does not need to take away your tools or assets to manufacture the foam tool storage organiser – the survey and data capture are done off-site. The onus on the client is to ensure all the correct items and qtys are available with no surprise additions once there has been a design freeze.

Once all the data is captured it is fed into our meander software system – the image is uploaded, profiled and placed into the foam layout. Once complete and approved, the file is sent to the CNC router and machined accordingly. With some additional finishing and cleaning the foam is complete and ready for installation.

There are many benefits to having a foam tool system installed into the workshop storage trolley and tool storage cabinets. These include reducing loss of items, increasing pickings speeds, improving workforce morale, capitalising your assets and passing strict ISO audits.

There are many benefits to having a foam system installed including reducing loss of items, increasing pickings speeds, improving workforce morale, capitalising your assets and passing strict ISO audits.

GET IN TOUCH

Your storage challenge is unique and we treat it as such. We will work with you from the outset to develop your plans and create the perfect storage product solution for you.

Contact Us