Workshop Fit Out

Edwards is a global leader of vacuum and abatement. They are proud to lead the industry, pushing the boundaries of science to deliver innovative products which are intrinsic to everyday life, working in partnership with their customers and continually setting new standards. The headquarters is Burgess Hill, West Sussex.

Edwards is familiar with the quality of Polstore storage solutions through the machine side of the business, but it was the Emerging Technologies team who required their expertise this time round. We spoke with Senior Technician, Neil Harber, about his experience of working with Polstore.

The challenge

Edwards is a growing business. As well as needing additional space for R&D work and testing new systems, they also needed to house a growing team. Edwards invested in a new unit which needed a full fit out.

They were clear on the result they were looking for – functional working space which was robust enough for the heavy equipment they use, with plenty of storage to maintain a clean workshop.

From the outset, optimising the floor space of the new unit was key. Each individual storage unit had to be the most efficient use of that space. Presentation was also important. Customers would visit the workshop occasionally and Edwards wanted to be able to close off tools and equipment from view to present a tidy and professional workspace.

The brief and design process

Edwards approached Polstore to quote for this fit out, following the recommendation from the machine shop of their business. They already had Polstore storage units to store heavy duty expensive equipment and were extremely happy with the quality and durability of the units after many years of repetitive use.

As part of the quotation process, MD Adam Lucas and Sales Executive Kristina Fordham visited the site, spending time getting to know Neil and his team and to fully understand their requirements. They took measurements and discussed potential solutions before presenting a suggested floor plan to clearly demonstrate how Polstore storage could meet their needs. Once Neil and the team were happy with the proposed solution, installation dates were then agreed.

The solution

Edwards required storage solutions to accommodate heavy duty items as well as smaller components. The end solution comprised of:

- Heavy duty racking – this offered an efficient storage and retrieval process for the heavy machinery (1.5-2 tonne) and parts they used. The racking is installed by our highly experienced and qualified UK team who are SEIRS, Safe Contractor and SEMA approved.

- Workshop storage cabinets – Edwards ordered 10 cabinets to store electrical components and smaller items. The modular design allowed Edwards to achieve drawer configurations which matched their requirements. This change alone reduced the amount of storage they needed whilst maintaining a high level of organisation. Cabinets are manufactured from high quality steel and can, if required, hold drawer load capacities of up to 200kg.

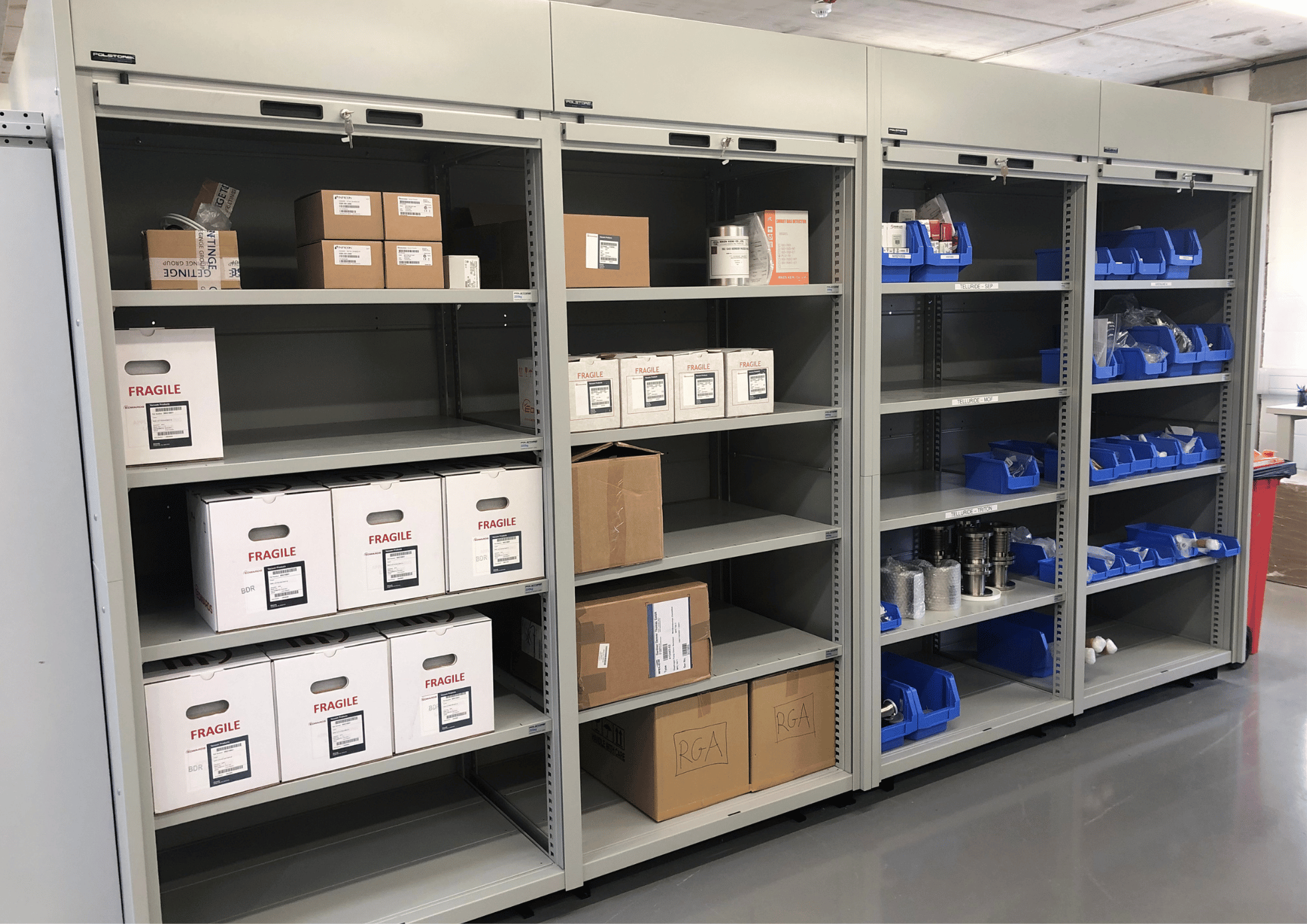

- Roller shutter cabinets – being able to hide away tools and equipment when clients were on site was important to Edwards, so they invested in 8 roller shutter cabinets which allowed them to keep the unit looking clean, tidy, and professional.

- Shadow boards – these were placed at the ends of cupboards to house strops, shackles and other components which were previously stored in bins or cupboards. The shadow board allowed the items to be hung up and easily identified if any were missing. Another benefit was all the equipment was laid out and ready for onsite inspections.

As the unit evolves, Edwards wants the storage units to grow with them which means being able to easily relocate cabinets around the workshop. To do this, the drawer and roller shutter cabinets are secured to a pallet truck base as opposed to fixed to the floor. This is a semi-permanent fixture which means they can be lifted and relocated in the future.

The installation

The Polstore team kept Edwards regularly updated from the time the project was approved through to the first day of installation. As units were being delivered, Neil’s team would be contacted so they always felt assured the installation was running as planned.

The installation took one week, and Neil commended the professionalism and ethos of the team:

“Installation and setup were brilliant. Each day they tidied up after themselves and left the unit clean. Nothing was ever too much trouble. They were very accommodating, and Adam and Kristina personally checked in during and after the installation.”

Occasionally, items can be damaged during transit. When instances like this occur, the team will ensure that replacement items are delivered as soon as possible. Neil commented: “There were a couple of damaged items during transit, but these were quickly replaced even during the install time. They kept us up to date at all stages.”

The result

Edwards now has a fully kitted out workshop to accommodate their business growth. The storage space has been optimised, with previous storage units replaced by cabinets which are half the size but provide more organisation and efficiency. They know that Polstore storage cabinets will last decades of heavy use in a demanding environment. The units can be relocated as the business grows further ensuring that the units provide optimum efficiency for the tasks at hand.

Tools and equipment can also be closed off from view when clients are onsite, adding to the professional look of the workshop.

The Edwards team were also impressed that each storage unit came with safe working load stickers direct from the manufacturer. The health and safety manager at Edwards found this to be a real benefit.

Why Polstore?

Aside from already having a recommendation based on the quality of Polstore storage solutions, Polstore was far more competitive on price. Edwards obtained quotes from other suppliers and were surprised at the additional installation charges applied on top of the product prices. The lead times were also double what Polstore had proposed.

Speaking of his experience of working with Polstore, Neil shared:

“We would 100% recommend Polstore to anyone! The team were in contact with us the whole time. Nothing was too much trouble and when issues arose, they resolved it in a timely manner. They spent a lot of time working with us to get everything right. I honestly couldn’t fault them. The whole team was fantastic.”

If you’re planning a new workshop space or to improve the efficiency of the space you currently have, speak to our highly experienced team about the result you’d like to achieve. Contact us on 0800 008 6861 or email us on enquires@polstore.co.uk.

Installation and setup was brilliant. Clean and efficient, nothing was too much trouble. 100% we would use Polstore again. I’d recommend them to everyone!

Neil Harber

Senior Development Technician

GET IN TOUCH

Your storage challenge is unique and we treat it as such. We will work with you from the outset to develop your plans and create the perfect storage product solution for you.

Contact Us