The Airforce Repair Enhancement Programme (AFREP) is responsible for fixing the unfixable. The original vision for AFREP was to save the USAF money through repairs however that vision has significantly broadened. Today, AFREP helps to sustain the fleet.

AFREP is part of the 355th maintenance group and made up of maintainers classically trained to repair A-10s, C-130s and HH-60s as well as crew chiefs, electricians, and avionics specialists. This team carries various specialist equipment with them in order to be able to fix anything, whether it’s the fleet itself or equipment back at base.

The return on investment for repairs is clear to see. For example, a replacement part of for the 7.62mm/.50 calibre machine gun on an HH-60G Pave Hawk would cost $84,000. AFREP can repair the part for $2,000 and the $82,000 saving can then go back into the USAF funds and dispersed where it is needed.

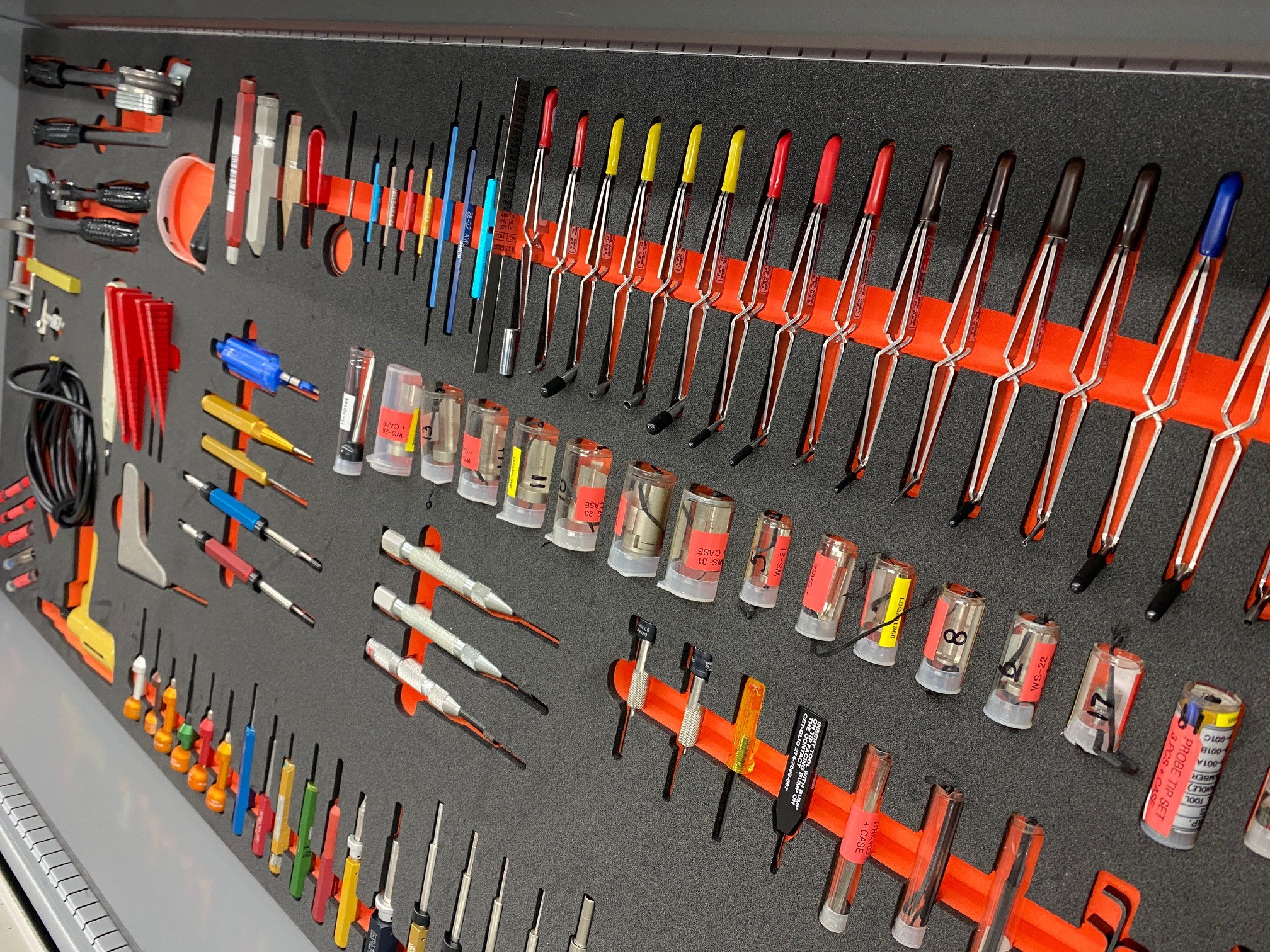

Clever storage to house the tools for every job

The challenge for AFREP is that they could be asked to repair anything therefore they need tools and equipment to be able to solve every type of problem. Storing full tool kits to cover every eventuality needs to be organised so that the team can find exactly what they need, when they need it.

The team also need to be able to safely transport tools and equipment around the base for repairs which can’t take place in the workshop. Moving expensive equipment around opens up the potential for items to go missing so giving them an identifiable place to live and be securely stored is essential.

Organisation is power

Polstore has a close working relationship with USAF. The ideal solution for the AFREP team was Polstore routed foam shadow boards and foam inserts. This storage solution was originally devised to meet the safety requirements of the aerospace industry – ensuring that tools used in the construction and maintenance of aircraft are never misplaced and instantly located.

The foam inserts are bespoke designed to the exact requirements of the tools and assets being stored. To achieve this, we use the latest CAD/CAM software for the data capture, profiling and design. In circumstances where the items are weapons related or of a sensitive nature, we can train units to complete the data capture themselves.

Once approved, our Trend CNC 3-axis machine brings the design to life. Even with unique designs, Polstore foam inlays are extremely cost effective. They are manufactured from a material known as ‘plastazote’: a man-made polyethylene, which is chemically inert, flexible, oil proof, waterproof, non-toxic and odourless. To achieve an exact fit around the items, we use different grades of plastazote to create a variety of thicknesses.

Exceptional storage for an exceptional team

AFREP use Polstore foams in a variety of storage solutions. At base, foam inlays are used within our lockable drawer cabinets to house tools and fixtures. For equipment when needs to be mobile, AFREP use foam inlays in protective shock proof cases. These typically store tools, equipment as well as guns and weaponry for other USAF units.

Foam shadow boards have also been supplied to the Fuel Systems support unit as military standards require every item to have an identifiable location. As Polstore supply storage systems across the USAF, the shadow boards for are top black foam with a green base inlay, which matches the Squadron colours.

Transform your storage challenges with Polstore foams

Foam shadow boards and inlays are a core component of our storage solutions. The versatility as well as cost-effective design and manufacture make this a popular choice across our military clients.

Contact our experienced team today to discuss your storage challenges.

GET IN TOUCH

Your storage challenge is unique and we treat it as such. We will work with you from the outset to develop your plans and create the perfect storage product solution for you.

Contact Us